1. Introduction

The cost of producing solar panels has significantly increased as a result of the recent increase in silicon prices. Due to the rising cost of silicon, an essential component in the production of solar panels, the total production costs have increased. The solar energy sector is directly impacted by this increase in production costs since it has an impact on how affordable and accessible solar technology is for customers. Given the crucial role silicon plays in the production of solar panels, it is imperative that both consumers and industry professionals comprehend the ramifications of price variations.

2. Silicon Price Hike: Causes and Consequences

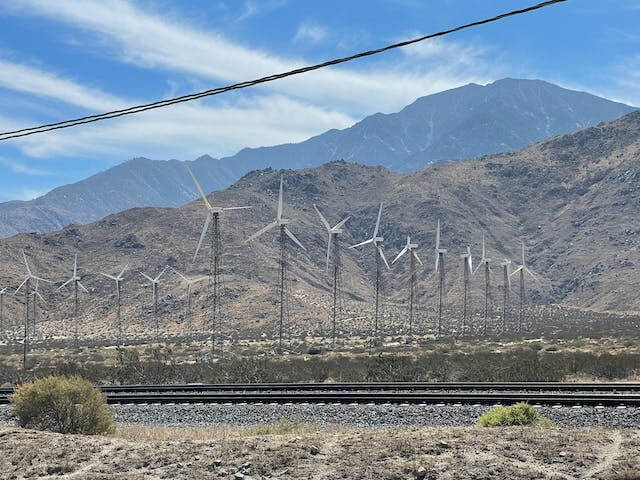

The cost of producing solar panels has increased dramatically as a result of the recent surge in silicon prices. This spike in silicon costs has been caused by a number of factors, such as increased demand for solar panels, problems with the supply chain, and trade disputes. The need for silicon, a crucial component of solar panels, is rising along with the demand for renewable energy. Prices have increased as a result of the strain this rise in demand has placed on the already fragile silicon supply chain.

The cost of manufacturing solar panels as a whole is directly impacted by the increase in silicon costs. The production of photovoltaic cells, the components that make up solar panels, requires silicon. The cost of making these cells and, by extension, the solar panels themselves, rises in tandem with the price of silicon. The makers of solar panels are faced with a challenge in maintaining competitive pricing amidst rising prices due to the increase in production costs.

The solar panel sector is facing serious issues as a result of the increase in silicon prices. The cost of silicon has significantly grown as a result of supply chain interruptions and rising demand, which has an impact on the production costs related to solar panel manufacture. For the renewable energy industry to continue growing and innovating, addressing these obstacles is essential.

3. Industry Perspectives: Experts' Views

Concerns regarding the impact of the recent spike in silicon costs on the solar energy sector have been voiced by industry professionals. Many predict that the cost of producing solar panels would rise dramatically as a result of the rising price of silicon, which might potentially impede the expansion of the solar sector.

Experts say that the cost and competitiveness of solar energy as a renewable energy source may be impacted by the increase in silicon prices. The higher production costs could potentially hinder the uptake of solar technology, with implications for manufacturers and consumers alike.

Industry experts are debating possible ways to slow down the cost increase in response to this challenge. Concentrating research and development efforts to increase solar panel efficiency and hence lower the silicon required for their fabrication is one suggested approach. To reduce reliance on silicon, another tactic is to invest in other materials or diversify sources of silicon.

Certain analysts contend that incentives and policy support are essential for counterbalancing the higher production costs. Despite growing material costs, solar energy can become more competitive with the support of government subsidies or tax breaks.

Industry viewpoints emphasize the necessity of taking preventative action to deal with the effects of the spike in silicon prices on solar panel manufacturing costs and guarantee the solar energy sector's sustainable growth.

4. Market Dynamics: Impact on Solar Panel Affordability

The cost of producing solar panels has increased by about $34 per panel as a result of the recent spike in silicon prices. This increase in production costs has a direct impact on consumers' ability to get and buy solar panels, which could impede the general acceptance of renewable energy and sustainability objectives.

Prices for solar panels will unavoidably grow due to increased production costs, making them less accessible to consumers. As a result, when looking to invest in solar energy systems, individuals and organizations could encounter more financial obstacles. This could impede attempts to lessen dependency on conventional fossil fuels and delay the adoption of renewable energy goals.

The higher price of solar panels can make them less appealing as a sustainable energy source when compared to other options. Due to lower upfront costs, consumers and businesses may decide to reassess their investment decisions as a result of this shift in affordability, maybe favoring non-renewable energy sources.

The effect that solar panel affordability has on sustainability objectives may have a broad influence. The deceleration in the implementation of solar energy systems due to increased expenses could postpone progress in mitigating greenhouse gas emissions and addressing climate change. In order to guarantee that renewable energy continues to be an affordable and accessible choice for everyone, it is imperative that these market dynamics be addressed and workable solutions investigated.

5. Technological Innovations Amidst Cost Challenges

In the solar sector, technological advancements are essential, particularly in light of the recent surge in silicon prices, which has raised the cost of producing solar panels by around $34. Thankfully, a number of cutting-edge techniques and technologies are being developed to offset these increased costs. For example, some businesses are investing in cutting-edge manufacturing processes like perovskite solar cells, which have the potential to drastically lower production costs. Comparing these cells to conventional silicon-based panels, the former provide cheaper material costs and higher efficiency.

The goal of research efforts is to enable more economical production procedures for solar panels. The evolution of thin-film solar technology, which makes use of smaller layers of photovoltaic materials to build solar panels, is one such example. This method not only uses less material but also gives panel designers and integrators more creative freedom. Robotics and factory automation advances are optimizing production procedures, resulting in increased productivity and lower labor expenses.😐

As I mentioned earlier, the solar business continues to be at the forefront of technological innovation, even with the obstacles provided by increased silicon prices. In addition to reducing financial demands, these initiatives promote sustainability and the broad use of renewable energy sources. Therefore, maintaining research and development spending will be essential to guaranteeing a future where solar energy is more widely available and reasonably priced.

6. Policy Implications: Government's Role

The cost of producing solar panels has increased due to the recent spike in silicon prices, which presents difficulties for the renewable energy sector. It is imperative that governments investigate possible policies and tactics that can assist in addressing the effects of these increasing expenditures as they deal with this issue.

Governments could take the following course of action: they could introduce incentives or subsidies meant to encourage the continuous expansion of renewable energy. Governments can help offset the rising production costs and ensure that the spread of renewable energy sources stays economically viable by providing financial support or tax incentives to solar panel manufacturers.

Lawmakers can look at trade agreements and laws that would lessen the effect of rising silicon costs on the manufacturing of solar panels. In order to stabilize or lower the cost of importing silicon, this may entail negotiating trade agreements and tariffs. This could assist lower the total manufacturing costs for solar technology firms.

Governments should fund projects aimed at advancing the cost and effectiveness of substitute materials for solar panels through research and development. Policymakers can reduce dependence on silicon, diversify the components used in solar panel manufacturing, and potentially mitigate the consequences of price swings by encouraging innovation in this space. 😃

Strategic policy initiatives to support renewable energy progress while balancing economic realities should be carefully explored as governments manage the ramifications of rising solar panel production costs. Policymakers can be a major player in resolving these issues and guiding the renewable energy industry toward resilience and sustainability by taking aggressive and focused measures.

7. Global Perspective: Effects on International Solar Markets

The global solar markets are significantly impacted by the recent increase in silicon prices. The rising cost of silicon, a necessary component in the production of solar panels, poses a danger to raise the total cost of solar panel production by about $34. The competitiveness of the market and the dynamics of international trade may be impacted by this increase in manufacturing costs.👶

Different regions are probably going to be impacted differently by the pricing change. Nations possessing robust internal manufacturing capacities and availability of substitute raw material sources could be more capable of managing the escalated production expenses. However, it might be more difficult to continue producing solar panels at a reasonable price in areas that mainly rely on imported silicon.

The aforementioned circumstance emphasizes the interdependence of the worldwide solar sector and stresses the significance of broadening supply networks and promoting ingenuity to minimize possible disturbances resulting from variations in the cost of raw materials. It is critical to comprehend how this pricing change affects the capacity of various regions to absorb higher production costs in order to assess the robustness of global solar markets and trade dynamics.

8. Supply Chain Disruptions and Resilience Strategies

Concerns over possible interruptions in the supply chain for the manufacture of solar panels have been raised by the recent spike in silicon prices. Since silicon is an essential component of solar panels, an increase in its price is anticipated to have an effect on the cost of production as a whole. The expected increase in manufacturing costs for a standard-sized solar panel due to this rise is $34.

Businesses in the solar energy sector are assessing the possibility of supply chain interruptions brought on by higher silicon prices. One possible cause of the disruption is the inability to find a sufficient supply of silicon at reasonable costs. In order to reduce this risk, businesses are revising their silicon buying policies and looking into alternate silicon suppliers.

Businesses are modifying their supply chain strategy in response to these difficulties in order to maintain operational resilience and continuity. To ensure steady pricing and availability, some are broadening the range of silicon vendors they work with or extending longer-term contracts with them. Optimizing inventory management and investigating technical innovations to lessen dependency on expensive resources are receiving more attention.

By implementing these adaptive techniques, the supply chain will be more resilient to price increases and future shortages of vital parts like silicon. In the ever-changing solar energy market, organizations need to be proactive in order to stay competitive and manage through uncertainty.

9. Consumer Education: Understanding Cost Determinants

Silicon Price Hike Increases Solar Panel Production Cost By Around

Solar panels are becoming a more and more popular choice for homes and companies looking to lower their energy expenses and carbon footprint as the world shifts to renewable energy. The price changes of silicon, a critical component in the creation of solar panels, are one major factor impacting the affordability of solar panels.

Customers must understand how price fluctuations for silicon can affect the total cost of solar panels. The cost of producing solar panels has increased by about $34 per panel as a result of the recent jump in silicon prices. Customers eventually bear the brunt of this expense, which raises the total amount of money needed to install solar energy equipment.

When thinking about installing solar panels, it's critical for customers to make informed judgments in light of current market developments. Customers are better equipped to weigh their options and make wise decisions when they are aware of the factors that determine costs, especially the impact of silicon pricing. Consumers may maximize the value and efficiency of their solar panel investments while navigating through price swings by remaining knowledgeable about market dynamics and cost drivers.

Customers should seek advice from reliable sources and think about speaking with business experts who can offer insights into pricing dynamics and market trends while weighing their solar panel options. When customers have a better grasp of how cost factors, like silicon pricing, affect overall spending, they can make more informed selections that fit their budgets and sustainability objectives.

As I mentioned earlier, enlightening customers on the variables that affect solar panel prices, such as the effect of changes in silicon prices, gives them the ability to deal with market shifts more skillfully. Consumers may make wise decisions that support their shift to sustainable energy solutions and maximize their long-term solar technology investments by remaining educated and, when needed, obtaining professional advice.

10. Environmental Sustainability in Light of Increased Costs

Concerns concerning the possible effects on long-term environmental sustainability initiatives have been raised by the recent spike in silicon pricing. It's important to look into how initiatives to promote renewable energy and mitigate climate change can be impacted by the $34 increase in solar panel production costs.

Notwithstanding the financial obstacles, efforts are nevertheless being carried out to guarantee that the transition to a greener future continues. To lessen the effect of the increase in silicon prices on the cost of producing solar panels, businesses are looking into cutting-edge technology and process improvements. Diversifying raw material procurement tactics is becoming increasingly important in order to reduce exposure to price swings. Despite the present economic difficulties, these steps are intended to keep the shift toward sustainable energy options moving forward.

The goal of ongoing research and development is to improve the cost and efficiency of energy sources other than conventional silicon-based solar panels. This covers the development of thin-film solar technology as well as the investigation of novel materials for the production of solar cells. The sector seeks to balance economic demands with environmental sustainability objectives by investing in research and expanding its alternatives for technology.

Based on the aforementioned information, we can infer that industry stakeholders are actively seeking ways to overcome the constraints posed by rising manufacturing costs to environmental sustainability initiatives. Despite the present state of the economy, the dedication to technical innovation, diverse sourcing, and continuous research represents a shared resolve to move toward a greener future. In spite of shifting market conditions, the renewable energy sector's resilience will be crucial to sustaining progress toward environmental sustainability goals.

11. Investment Outlook: Evaluating Opportunities and Risks

The cost of producing solar panels has increased by about $34 per panel as a result of the recent surge in silicon prices. Significant ramifications have resulted for the solar industry, namely for businesses that produce solar panels. In light of the growing cost of production, investors must now assess the potential benefits and risks of funding these businesses.

The possible effect of higher production costs on a company's bottom line must be taken into account when evaluating investment opportunities in solar panel manufacturing companies. Businesses that can use cutting-edge technologies or substitute materials to control and reduce these growing expenses can make for appealing investment prospects. Investors want to assess these firms' competitive standing in the dynamic solar industry, including variables such worldwide regulatory rules, market demand, and technology improvements.

Nonetheless, it is imperative for investors to take into account the possible hazards associated with the rising expenses of manufacturing. Businesses who can't adjust to these cost increases can see pressure on their margins and a decline in profitability, which would eventually affect the performance of their stock. For producers of solar panels, price fluctuations for raw materials and interruptions in the supply chain could present new difficulties.

Notwithstanding these difficulties, investors might take advantage of possibilities in this changing market. Long-term winners may be those businesses that show resiliency and flexibility in controlling manufacturing costs while preserving product quality and competitiveness. The solar sector as a whole continues to have a bright future as long as international efforts to promote renewable energy sources are strengthened.

Based on the aforementioned, it is evident that evaluating investment considerations pertaining to solar panel manufacturing companies necessitates a comprehensive comprehension of the potential effects that increasing production costs may have on their financial performance and competitive positioning. While higher production costs may pose dangers, investors may also be able to find businesses that can successfully manage these difficulties and prosper in the rapidly changing solar market. Making wise investing choices in this industry requires an understanding of these dynamics.

12. Conclusion and Future Trends

After putting everything above together, we can say that the cost of producing solar panels has gone up dramatically due to the growing price of silicon, an estimated $34 more per panel. This has affected solar sector manufacturers as well as consumers, creating difficulties for them to maintain profitable and competitive pricing.

In the future, supply chain interruptions and material pricing increases are expected to pose significant hurdles for the solar sector. Manufacturers may investigate new technologies or substitute materials in an effort to lessen the effect of skyrocketing silicon prices on manufacturing expenses.

A greater emphasis on renewable energy and sustainability may encourage funding for research and development of more affordable solar panel manufacturing techniques and materials. Amid these continuous changes, technological breakthroughs and shifting market dynamics are probably going to be major factors in determining how the solar energy industry develops in the future.